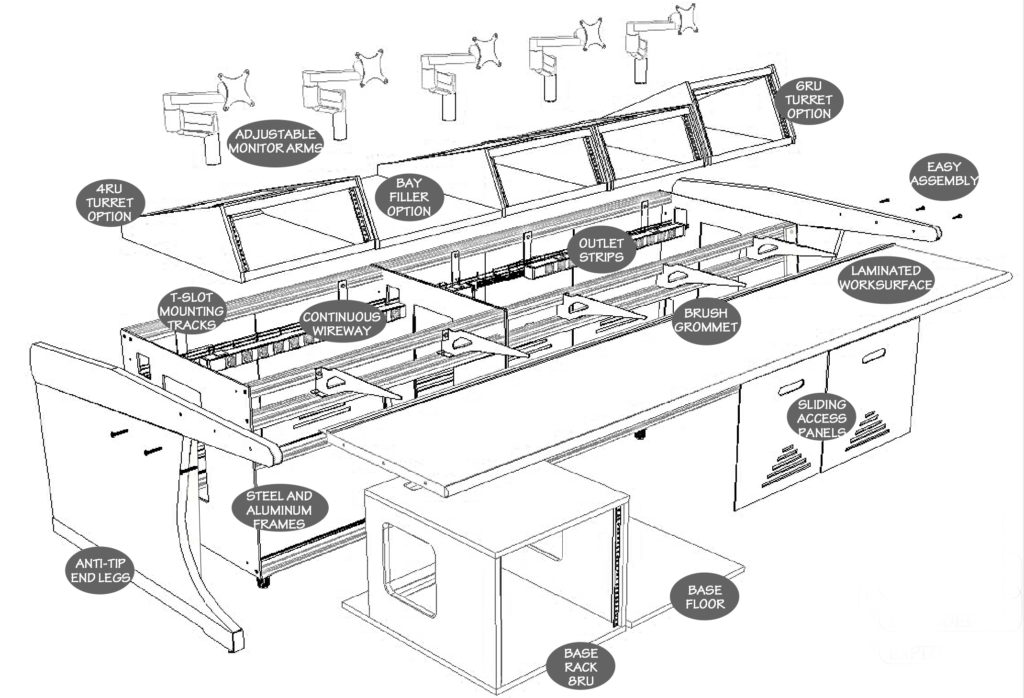

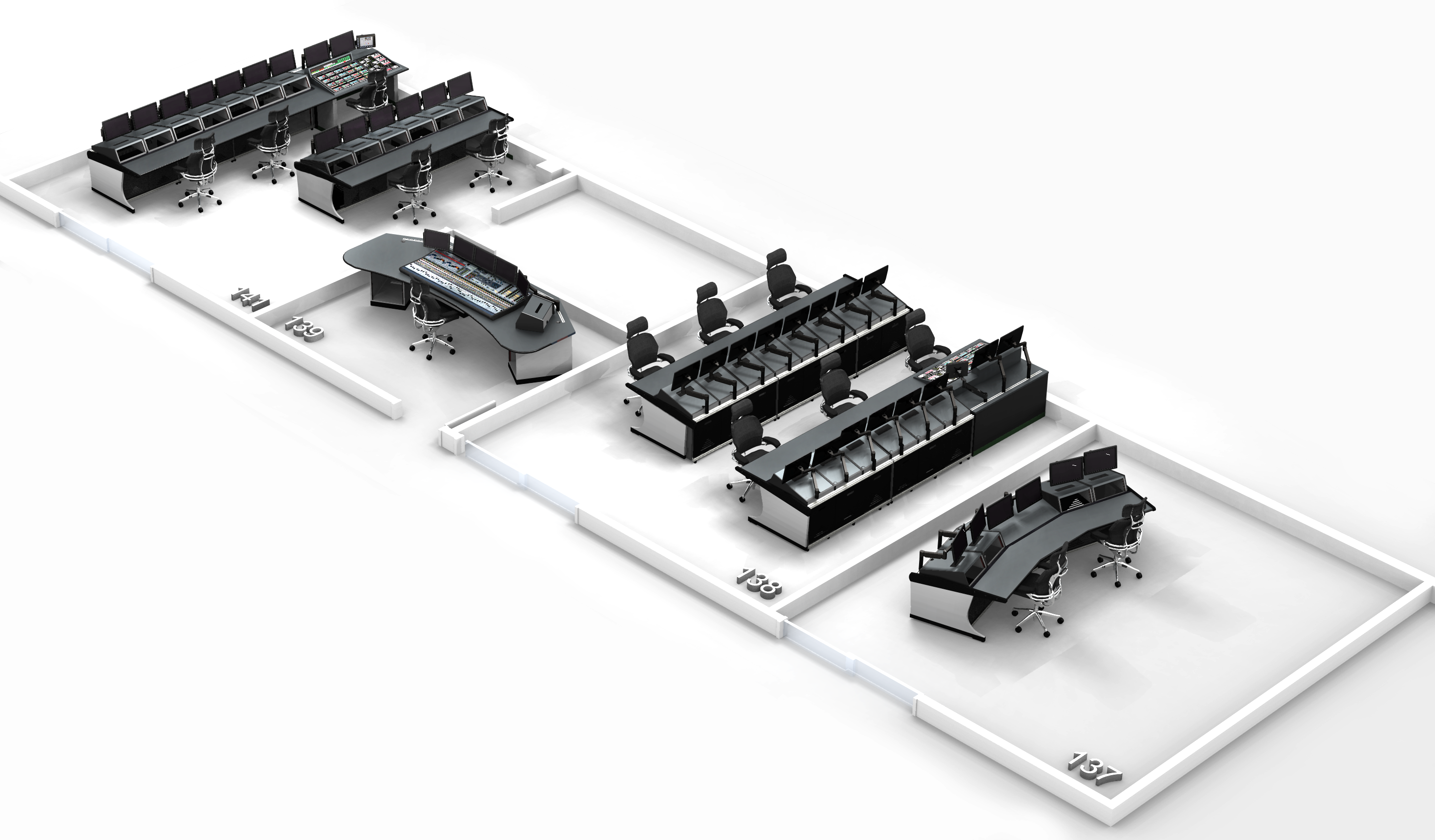

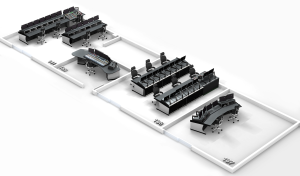

At Eastboard, we’ve added two 3D-printed plastic parts to our RACKBLOCKS consoles; these simple components have upgraded and simplified the assembly process, while also improving the strength and appearance of our consoles. We’re producing these in-house, on an as-needed basis. The ability to make small-batch, end-use parts, without up-front tooling costs, is still kind of amazing. And having the relatively instantaneous feedback about design iterations helps produce better parts. We’re not printing entire consoles – yet – but 3D printing has already solved some of our manufacturing concerns, and the as-yet undiscovered future applications seem endless. Every shop should have a 3D printer.

At Eastboard, we’ve added two 3D-printed plastic parts to our RACKBLOCKS consoles; these simple components have upgraded and simplified the assembly process, while also improving the strength and appearance of our consoles. We’re producing these in-house, on an as-needed basis. The ability to make small-batch, end-use parts, without up-front tooling costs, is still kind of amazing. And having the relatively instantaneous feedback about design iterations helps produce better parts. We’re not printing entire consoles – yet – but 3D printing has already solved some of our manufacturing concerns, and the as-yet undiscovered future applications seem endless. Every shop should have a 3D printer.

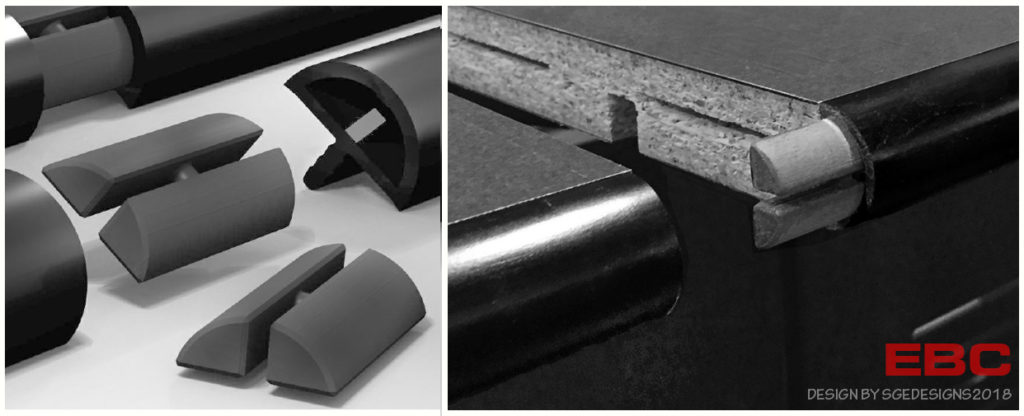

The first new part (above) is one that’s not even visible after assembly! On RACKBLOCKS console frames, our standard monitor arms are mounted to T-slot tracks. But there’s a conflict: the arm mounting cups are recessed to fit 3/8” hex head bolts, and our track system uses M8 fasteners. The metric hex heads are slightly smaller enough that the bolt heads rotate freely and don’t grip the recess, which required a cumbersome installation method. There had to be a better way. So I designed a thin hex adapter sleeve (0.03” wall) to convert the SAE recess to metric; the M8 bolts now fit tightly. These simple parts each use just ½ gram (about $0.02),of PLA, a reliable, easy-to-print, hard plastic, perfect for this application; no need for exotic filaments. They’re quick to print, too; A batch of 12 took just under 2 hours, and they were usable right off the printer. Out of sight, but definitely not out of mind.

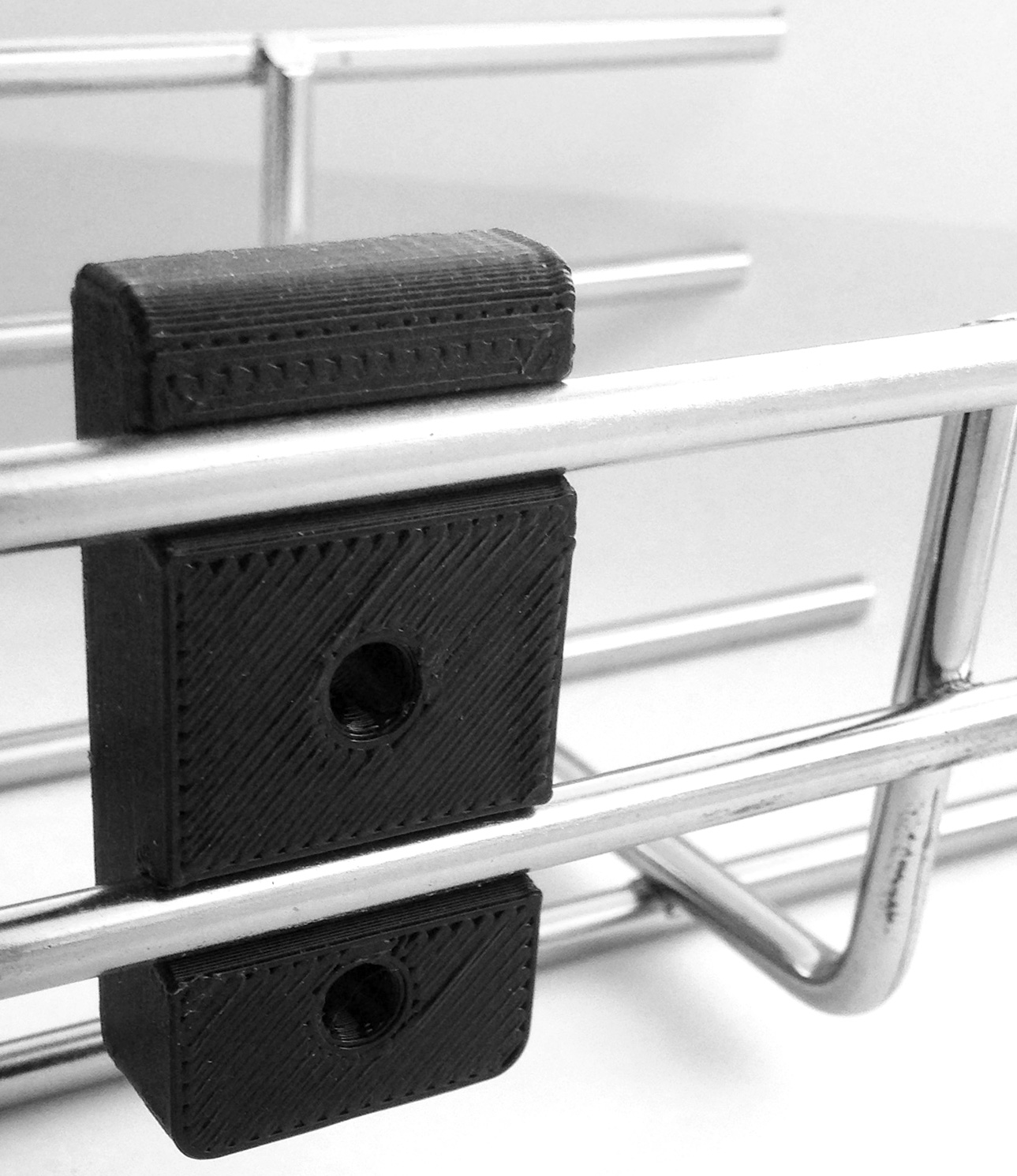

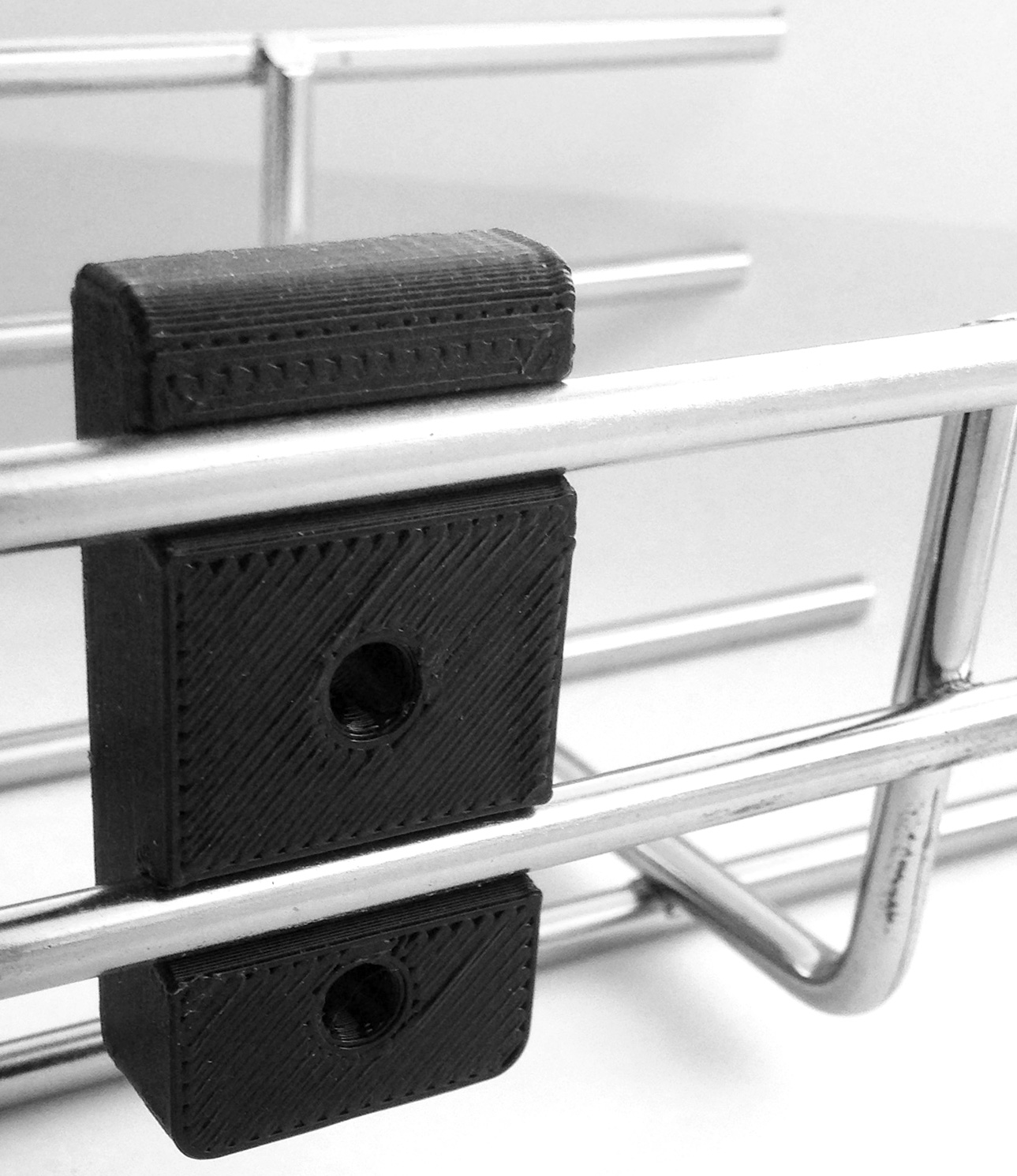

The second part (below) is a backplate for bolting power strips to the rails of the cableway in our RACKBLOCKS consoles. Although a very simple fitment, there was nothing commercially available, so we had improvised an attachment method. But there had to be a better way – and 3D printing was that way. We now have exactly the part needed, which functions better and looks more finished than the old method. We used PLA again, despite having stronger, carbon-fiber filled PETG available. Ease of printing is always a factor, and impregnated plastics generally require more attention; the carbon-fiber filled filaments especially, chew up and clog standard brass nozzles; they print best through steel nozzles with larger diameters. Since nozzle changes are time-consuming and unwelcome, and we’re aiming for simple, reliable production here, we just made the backplates thicker to add strength. Even so, each part requires only 10 grams of material (about $0.40), and takes just 22 minutes to print. And they get the job done in style.

DOWNLOAD PDF

At Eastboard, we’ve added two 3D-printed plastic parts to our RACKBLOCKS consoles; these simple components have upgraded and simplified the assembly process, while also improving the strength and appearance of our consoles. We’re producing these in-house, on an as-needed basis. The ability to make small-batch, end-use parts, without up-front tooling costs, is still kind of amazing. And having the relatively instantaneous feedback about design iterations helps produce better parts. We’re not printing entire consoles – yet – but 3D printing has already solved some of our manufacturing concerns, and the as-yet undiscovered future applications seem endless. Every shop should have a 3D printer.

At Eastboard, we’ve added two 3D-printed plastic parts to our RACKBLOCKS consoles; these simple components have upgraded and simplified the assembly process, while also improving the strength and appearance of our consoles. We’re producing these in-house, on an as-needed basis. The ability to make small-batch, end-use parts, without up-front tooling costs, is still kind of amazing. And having the relatively instantaneous feedback about design iterations helps produce better parts. We’re not printing entire consoles – yet – but 3D printing has already solved some of our manufacturing concerns, and the as-yet undiscovered future applications seem endless. Every shop should have a 3D printer.